-

Solutions

-

OEM Products

Pretech: Smart Display & Control Devices

OEM/ODM Solutions

OEM/ODM Solutions

Pretech specializes in the design and manufacturing of cutting-edge smart display and control devices. As a leading provider of OEM/ODM solutions, we offer customized smart devices tailored to the unique needs of global markets. Our commitment to innovation, quality, and compliance ensures that our products meet the highest industry standards. With a focus on IoT-driven technologies in HMI, healthcare, automotive infotainment, and POS, Pretech is your one-stop solution for smart devices that drive efficiency and enhance user experience.

Explore Our Customized

Smart Devices Factory

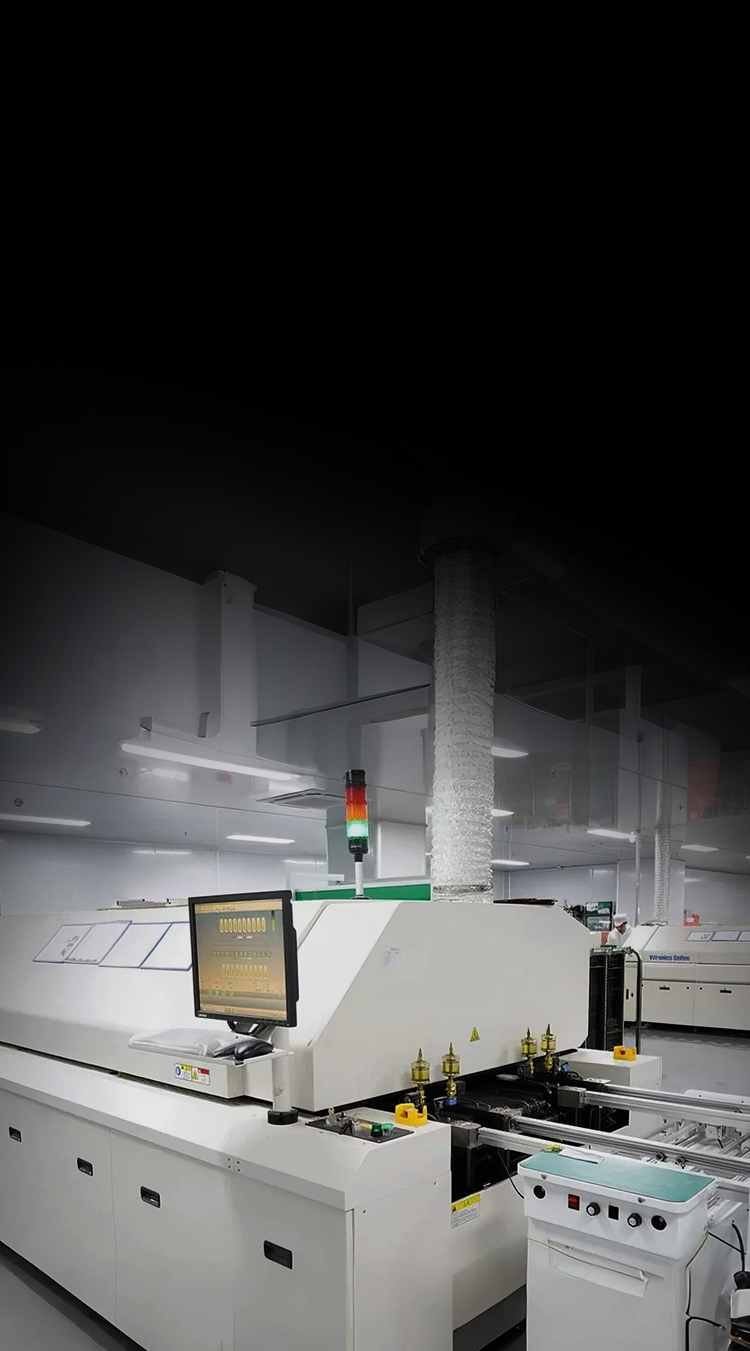

Smart Display and Control Devices Manufacturing Solution

Pretech Factory is a Specializing in the production of tablet Pcs and laptops and ODM smart conrol and display devices based on different industrial needs, we offer a comprehensive range of services from component sourcing to final product assembly.

Our state-of-the-art laboratories are equipped with the latest testing equipment, ensuring that our products can withstand the rigors of daily use. With devices like the battery capacity meter, dust and water resistance testers, and life cycle simulators, we maintain the highest standards of durability and reliability.

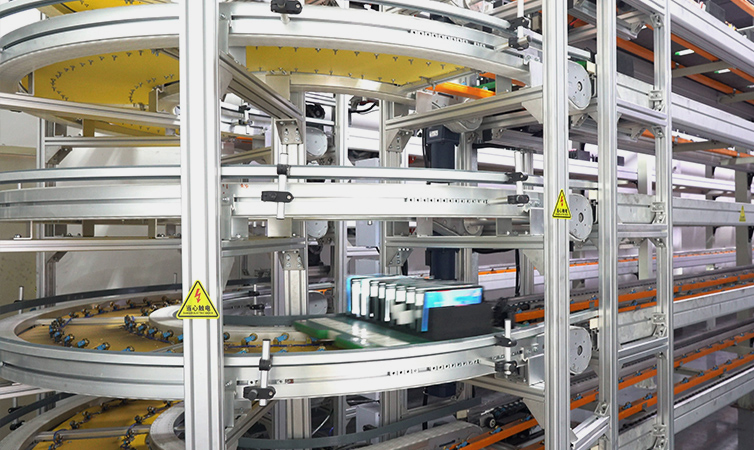

Our production lines are a marvel of automation and precision. Six tablet assembly lines and four laptop assembly lines churn out high-quality devices, each passing through rigorous testing stages. Our fully automated aging room can handle up to 10,000 tablets at a time, setting us apart in the industry.

In addition to production, we boast an independent mold factory, complete with CNC machines, EDM equipment, and a range of injection molding machines capable of producing large-scale plastic components. This vertical integration allows us to offer a one-stop solution to our clients, from mold making to final product assembly.

Our SMT line, featuring four high-speed Yamaha machines, caters to the production of PCBAs for a variety of applications, demonstrating our flexibility in serving both internal and external orders.

At Pretech Factory, we pride ourselves on being a full-service smart devices manufacturer,delivering excellence from concept to completion.

Our state-of-the-art laboratories are equipped with the latest testing equipment, ensuring that our products can withstand the rigors of daily use. With devices like the battery capacity meter, dust and water resistance testers, and life cycle simulators, we maintain the highest standards of durability and reliability.

Our production lines are a marvel of automation and precision. Six tablet assembly lines and four laptop assembly lines churn out high-quality devices, each passing through rigorous testing stages. Our fully automated aging room can handle up to 10,000 tablets at a time, setting us apart in the industry.

In addition to production, we boast an independent mold factory, complete with CNC machines, EDM equipment, and a range of injection molding machines capable of producing large-scale plastic components. This vertical integration allows us to offer a one-stop solution to our clients, from mold making to final product assembly.

Our SMT line, featuring four high-speed Yamaha machines, caters to the production of PCBAs for a variety of applications, demonstrating our flexibility in serving both internal and external orders.

At Pretech Factory, we pride ourselves on being a full-service smart devices manufacturer,delivering excellence from concept to completion.

Customized Smart Display and Control Devices Solution

We provide the turn-key ODM solutions for certain customers who have specific needs which an' tbe satisfied

by existing devices on the market.

by existing devices on the market.

-

Interactive loT SolutionsWall-mounted Tablet with POE

Interactive loT SolutionsWall-mounted Tablet with POE

Wall-mounted Panel Gateway

Smart Gateway Hub with Cellular Network

Tablet PC with Docking Station for Smart Air Conditioner

Smart Wall Panel Monitor

Door Control System Tablet

Meeting Conference Schedule Display -

HMI SolutionsTablet PC Open Frame for Smart Coffee Machine

HMI SolutionsTablet PC Open Frame for Smart Coffee Machine

Android Touch Panel for Smart Cooker Panel

Digital Signage for Vending Machine

5 inch Android Tab for E-Bikes

Smart Android Touch Screen for Home Gym -

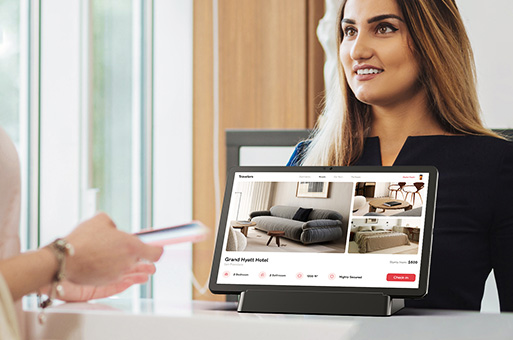

POS SolutionsSmart Tablet Menu

POS SolutionsSmart Tablet Menu

Kitchen Display with NFC

Tablet PC for Feedback Management

Smart Device for Payment Terminal -

Smart EducationTablet PC with stylus for Students Learning

Smart EducationTablet PC with stylus for Students Learning

Tablet PC for Students Learning with charging docking -

Healthcare SolutionsSmart Device for Skin Care

Healthcare SolutionsSmart Device for Skin Care

Blood Glucose Meter Dongle for Medical Use

Senior Care Tablet PC

Door Tablet for Clinics, Private and Public Hospitals

Therapeutic device for kids

Smart Display with AR for Kids -

Multimedia PlayerPortable Translation Equipment

Multimedia PlayerPortable Translation Equipment

Smart Audio Guide

Portable Translation Equipment -

Car Infotainment SolutionsProfessional OBD Tablet PC for Repair Shop

Car Infotainment SolutionsProfessional OBD Tablet PC for Repair Shop

On-Board Diagnostics Tablet PC for Drivers

High Accuracy Pro Android Portable Navigation

Car Rear Seat Entertainment System -

-

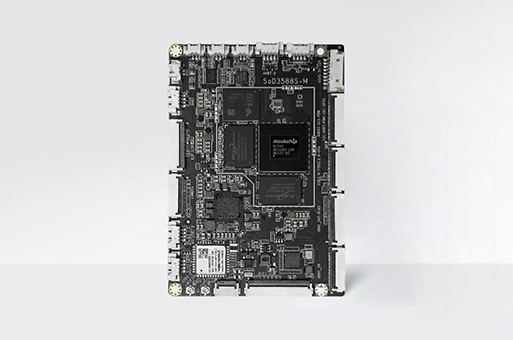

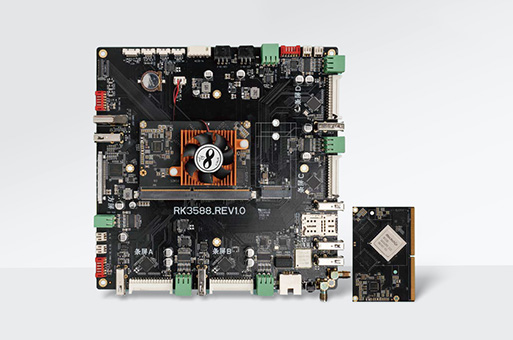

SBCRK3588 V88

SBCRK3588 V88

RK3588S SOD3588S-M

RK3568 T10

RK3566 SOD3566-M

RK3566 PMDP3566

RK3566 AIOT

RK3566 E6 -

SOMRK3588 SOM58

SOMRK3588 SOM58

RK3588 SOM58H

RK3588S SOM58S

RK3576 SOM3576

RK3568 SOM68

RK3566 SOM66

MT8788 SOM78

MT8781 SOM81

MT8768 SOM76 -

SOM and Carrier BoardRK3588 V58

SOM and Carrier BoardRK3588 V58

RK3588S GF3588S

RK3576 GM3576

RK3568 T68S

RK3566 ESOP

MT8788 W68

Premium Plant Equipment for High-Quality Smart Devices Manufacturing

Our factory is equipped with state-of-the-art machinery to ensure precision and efficiency in the

production of custom tablets, mobile phones, laptops, and other electronic devices. Key plant

equipment includes:

Automatic dispenser; Insertion life testing machine; The dielectric voltage withstand test; Battery capacity tester; Air shower door; Constant temperature and humidity tester; Heating machine; Radium IMEI&SN&ID; Bare-metal export; Simulation transportation vibration tester; Testing machine; Tablet press machine; Mobile phone coupling tester and Swaying wire machine

Each piece of equipment is integral to our ODM/OEM manufacturing process, ensuring that we produce high-quality, reliable products that meet industry standards.

Automatic dispenser; Insertion life testing machine; The dielectric voltage withstand test; Battery capacity tester; Air shower door; Constant temperature and humidity tester; Heating machine; Radium IMEI&SN&ID; Bare-metal export; Simulation transportation vibration tester; Testing machine; Tablet press machine; Mobile phone coupling tester and Swaying wire machine

Each piece of equipment is integral to our ODM/OEM manufacturing process, ensuring that we produce high-quality, reliable products that meet industry standards.

Manufacturing Capacity

Our manufacturing capacity supports the production of a wide range of high-quality electronic devices, including tablet PCs, mobile phones, laptops and netbooks. With 8 advanced production lines and a 12000 SQM factory, we specialize in scalable ODM/OEM solutions that deliver fast turnaround times and precision-crafted products tailored to meet the specific needs of clients in diverse industries.

-

Tablet PC300K+Month

-

Smartphone300K+Month

-

Laptop180K+Month

QC-Driven Pretech Factory

Unwavering Commitment to Quality, Reliability,

Precision in Smart Devices Manufacturing

Precision in Smart Devices Manufacturing

From design inception, we prioritize rich experience, deep customer usage understanding, and stable

supplier partnerships to ensure material consistency. Our rigorous design validation process

includes EVT and DVT stages, ensuring functionality and reliability. In production, IQC conducts

thorough incoming inspections, with full checks on LCDs and AQL sampling for components like

motherboards, TP, and batteries, performing capacity tests on batteries. Pre-mass production, we

conduct small-scale trials to simulate real-world usage and stress test products. Reliability trials

post-prototype confirm design integrity and component lifespans against specific usage scenarios.

During mass production, IPQC ensures process consistency, while QC oversees aging and final testing,

with OQC handling final inspections and preparations. Our commitment to quality control and

reliability testing at every stage guarantees products that meet and exceed industry standards.

Pretech's Advanced Laboratory

Ensuring Reliability and Durability in Custom Smart Devices

At Pretech, our commitment to product reliability is evident in our state-of-the-art laboratory, spanning 380 square meters and equipped with high standards. This lab is the backbone of our quality assurance, housing a range of specialized testing equipment designed to simulate various real-world conditions. From our 10-axis torque life testing machines capable of 10,000 cycles to our temperature shock chambers ranging from -20 to 60 degrees, we ensure that our devices can withstand the extremes. Our dust and waterproof testing instruments, as well as our paper, alcohol, and eraser abrasion testers, verify the durability of our displays. Furthermore, our keystroke life testing machines simulate up to 100,000 presses, ensuring longevity in high-use scenarios. With drop test and vibration testing equipment, we mimic transportation impacts and environmental vibrations to guarantee our products' resilience. This comprehensive approach to testing ensures that every Pretech device meets the highest standards of reliability and performance before it reaches the market.

Pretech's Advanced Aging Lab: Assuring Stability in the Production of Smart Devices

At Pretech, our aging laboratory is a testament to our dedication to product longevity and reliability. Our fully automated aging room is a standout feature, capable of simultaneously aging 10,000 tablet PCs, a capacity that sets us apart from our peers. This state-of-the-art facility is equipped to handle rigorous testing, ensuring that our tablets meet the demands of high-performance electronics in various industries, including education, healthcare, and corporate sectors. Our aging lab is not just a room; it's a hub of precision engineering, designed to simulate high-temperature and harsh environmental conditions to test the limits of our tablet PCs. This process is crucial for identifying and rectifying any potential flaws, thereby enhancing production efficiency and the quality of our tablets PCs. With an emphasis on energy efficiency and durability, our aging lab plays a pivotal role in the production workflow, ensuring that Pretech tablet PCs stand up to the standards of global clients seeking durable, high-performance devices. This commitment to excellence makes Pretech the preferred choice for custom tablet solutions, reinforcing our position as a leader in smart device manufacturing.

10,000+PCs

Concurrent Aging

Smart Device Manufacturing Process

Diverse Smart Devices: IoT, HMI, Healthcare, Infotainment, POS

Our custom tablet manufacturing process combines advanced technology with a high production capacity, featuring five efficient assembly lines and three specialized packing lines, enabling an annual output of 2,000,000 units. With strong OEM and ODM capabilities, we are well-equipped to handle the most demanding custom tablet production requirements, delivering high-quality solutions tailored to meet your specific needs.

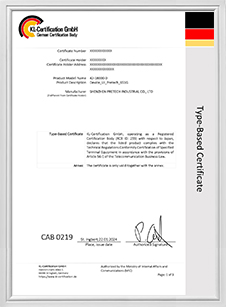

Pretech Factory: Global Standards Compliance

Pretech Factory is certified with ISO 9001 for quality management, ISO 14000 for environmental management, and BSCI for social compliance.

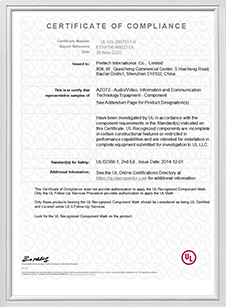

Pretech Smart Devices: Globally Certified Compliance

Pretech's products are designed to meet a variety of international certifications, ensuring compliance and quality across global markets. Our tablet PCs, smartphone ,laptop and smart devices are certified with ISED, CE, ROHS, JATE, WEEE, IMDA, UKCA, and FCC, demonstrating our commitment to safety, environmental standards, and regulatory requirements. Additionally, Pretech's products are equipped to achieve other product certifications, reinforcing our dedication to excellence in manufacturing.

-

FCC

FCC -

UL

UL -

JATE

JATE -

CE

CE -

ROHS

ROHS -

REACH

REACH -

KC

KC -

JATE

JATE -

ISED

ISED -

WEEE

WEEE -

UKCA

UKCA -

IMDA

IMDA

Contact Us

-

Send Inquriy NowWe'll respond within 24 hours of your request.

Send Inquriy NowWe'll respond within 24 hours of your request. -

Chat Now9:15am-6:30pm ( UTC+8) / working days

Chat Now9:15am-6:30pm ( UTC+8) / working days -

Send Inquriy NowEmail: admin@pretech-e.com

Send Inquriy NowEmail: admin@pretech-e.com

Phone: +86-755-23051989

Phone: (86) 13129558030

Address:808, 8F, Qiancheng Commercial Center, 5 Haicheng Road, Baoán, Shenzhen

We'll help find the right solution for your business.

It all starts with understanding your needs – and your goals. Our team of specialists are ready to listen.

![[pics:title]](/static/upload/image/20250527/1748335269110976.jpg)

![[pics:title]](/static/upload/image/20250422/1745291185434898.jpg)

![[pics:title]](/static/upload/image/20250527/1748335269936699.jpg)

![[pics:title]](/static/upload/image/20250527/1748314788378981.jpg)

![[pics:title]](/static/upload/image/20250527/1748314788429570.jpg)

![[pics:title]](/static/upload/image/20250527/1748314788648390.jpg)